Battery Management System

Many different components contribute to the correct charging of electric cars, which we gradually address in our series Basics of Electromobility. This time we will focus on the Battery Management System, or BMS.

The battery is still the most expensive component of any electric car and, if mishandled, its service life can be considerably shortened and under unfavorable conditions, it also presents a safety hazard for the car itself and its crew. It is important to ensure the right conditions for individual battery cells and thus for the entire battery, which is what BMS takes care of.

An electric car and its components. Author: FirstEnergy Corp. (Licence CC BY-ND 2.0)

In this article we will summarize how batteries are designed, we will focus on what the external environment must be so that the battery can work optimally, how the BMS is designed, what are its main functions and at the end we will mention the main challenges in designing an effective BMS system.

Battery design

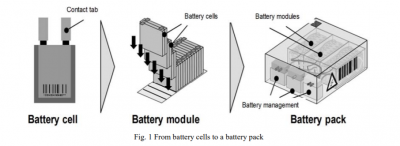

Although the electric car battery is talked about as a single thing, it actually consists of hundreds (and sometimes thousands) of battery cells that are connected in series or in parallel into battery modules. And these modules are then connected into a battery pack, or what everyone simply calls "a battery".

Thanks to this arrangement, it is possible to achieve the required capacity and energy, and at the same time it is easier to manufacture, install, but also to inspect and perform maintenance. We focus on the topic of batteries in more detail here.

Battery cell, module and pack. Source: https://www.semanticscholar.org/

Every manufacturer makes the battery slightly differently, uses different chemical compounds, or makes battery cells of different shapes. But it is always a type of lithium battery, which is the most efficient technology that we have so far. These batteries are more or less (depending on the specific compound) sensitive to temperature changes, overcharging or discharging too much, and in order to prolong their life as much as possible, these quantities need to be carefully monitored and controlled.

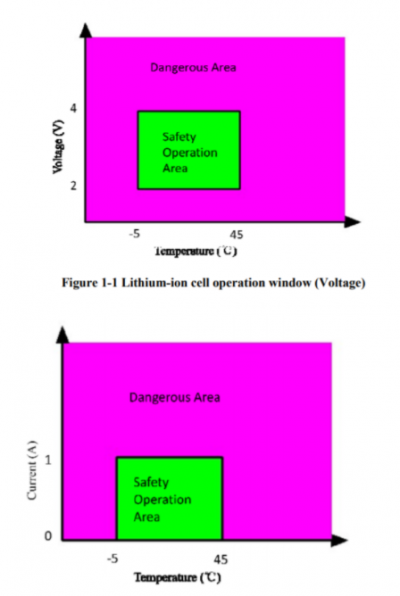

Lithium batteries are also prone to temperature leaks, which can occur due to several errors, such as charging too fast or discharging too quickly. The following graphs show the so-called Safety Operation Area. The green box represents the conditions under which lithium batteries are safe and work the best. The temperature should be between -5 and 45 ° C, the voltage between 2 - 4 Volts and the current from 0-1A. It is paramount to carefully monitor and ensure that the battery is in this "safety operation area".

Safety operation Area. Source: file:///C:/Users/Datart/Desktop/Battery Management System For Electric Vehicle Applications.pdf

BMS Construction

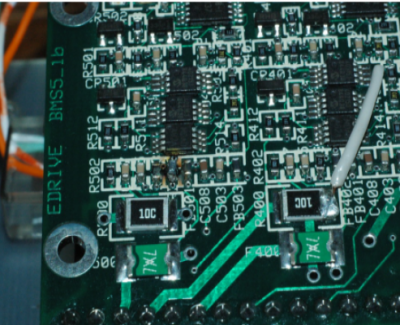

The design of the BMS corresponds to a large extent to the design of the battery. It consists of a battery monitoring integrated circuit (BMIC), a cell management controller (CMC) and a battery management controller (BMC).

Sistema de gestión de batería. Autor: carrott (Licence: CC BY 2.0)

The BMIC monitors the individual battery cells and must be able to quickly - in a matter of microseconds - inform the CMC of the situation so that the CMC or BMC is able to react and, if necessary, correct an unfavourable situation. In order to prevent temperature leaks, the BMIC needs to notice immediately the battery cell that is overheating and send this information further on as quickly as possible. The BMC must decide how serious the situation is, how to proceed, and the overheated cell must be shut down if necessary. And all of this must happen in the blink of an eye.

The accuracy of the measurement and the ability to respond to adverse conditions depend primarily on the frequency of communication from the BMIC to the CMC and BMC, the more often they communicate, the greater the chance that they will successfully resolve a situation that could be risky. However, it is not at all easy to design an effective communication network in an electric car due to electrical noise.

Of course, before correcting the BMS tries to prevent any unfavorable situation, so apart from the BMIC, CMC and BMC modules it also consists of circuits that balance the energy loads of different cells, in this way all cells work more or less the same and do not tend to cause problems. The issue of leveling is so important that we will discuss it much more in detail later on.

Unused battery cells. Source: https://www.analog.com/en/technical-articles/active-battery-cell-balancing.html

Depending on how complicated the electric car is, several intelligent microcontrollers may be added to monitor and control various specific tasks. Each BMS must be able to monitor not only the battery but also itself and it must be able to determine if alarms or prompts are real and not fake.

Basic functions of BMS

From all of the above, the functions of BMS are more than obvious, but to recap, we will list them one by one and stop at each one of them for a moment.

1. Discharge and charging control

Charging and discharging are the riskiest moments in the life of a battery. During AC charging, the charge control is partly taken care of by the on-board charger, which is responsible for converting AC current to DC, which is then sent in the required voltage to the battery. In the case of DC charging, the electric current goes directly to the BMS, which controls the charging and communicates with the DC station.

This function requires the whole system to be intelligent, because the parameters of the battery itself change over time (oxidation occurs at the terminals, changes in the capacity of the battery cells, etc.) and it is necessary that the charging always adapts to it in real time.

2. Determination of the current state of charge (State of Charge)

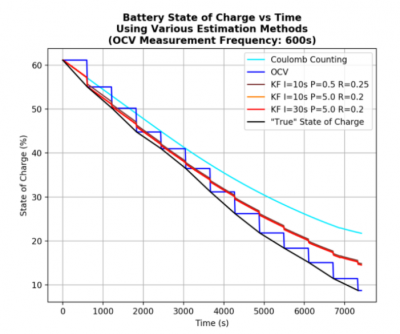

This is one of the most important functions, thanks to which the BMS can tell the driver how much longer he can drive. But determining the state of charge is not nearly as simple as it might seem. It is actually one of the more complicated problems in the development of BMS systems.

The current state of charge is defined as the ratio of the available capacity to the total capacity of the battery and can therefore take any value from 100% to 0%. And since the 'discharging' of the battery is an electron flow, it would seem that the amount of charge or discharge can only be measured. However, consumption is affected by many variables, such as current temperature, temperature change during discharge, current load, and more, so taking into account all of them is far from easy.

"KIA Future Infotainment System - CES 2014 - (5) - SMADEMEDIA.COM Galleria" by THE SMADE JOURNAL is licensed under CC BY 2.0

Determining the right value of state of charge is also complicated by the fact that the methods of accurate measurement are either too computationally complex or insufficiently accurate, and in addition the state of charge depends also on the parameters of the whole battery that change during its life, i.e. it depends on the state of health of the battery, which is even more complicated to determine.

As accurate measurement is not possible or is extremely impractical, the current state of charge is based on computer battery models. It is an estimate, though a qualified one. In the next chapter, we will focus on battery models a little more thoroughly.

3. Determination of State of Health

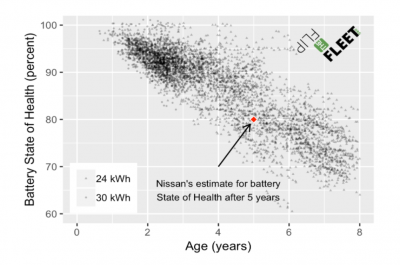

Battery health is defined as the ratio of the current full capacity to the full capacity of the battery at 0 kilometers. When you buy a battery, it has 100% health, which deteriorates with charging cycles.

Many studies agree that battery health is affected by temperature, battery charging current, number of charging cycles and other primary factors. However, not all processes in the battery are fully known, so there are no precise methods for determining battery health. As with determining the state of charge, it is necessary to rely on approximate computer models that take into account internal resistance, conductivity, self-discharge rate, capacity, energy received during charging, temperature during use, age, number of cycles, etc.

State of health of Nissan Leaf batteries over time. Author: Flip the Fleet. Source: https://flipthefleet.org/resources/benchmark-your-leaf-before-buying/

So far, there is no exact agreement between individual manufacturers which variables enter into the calculations and which models are to be used. Research and development continues to focus intensively on these topics. And as mentioned above, determining the state of health correctly is crucial to be able to determine the state of charge as closely as possible.

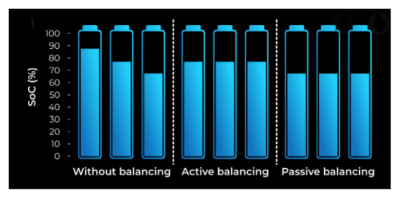

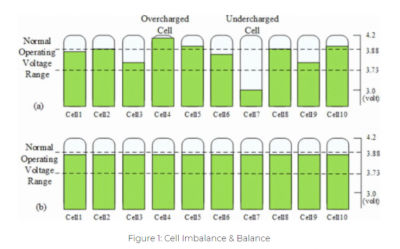

4. Charge balancing

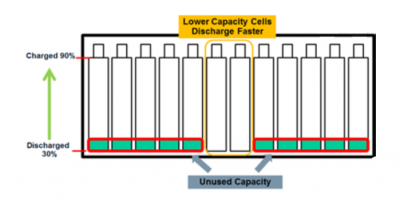

Balancing the charge and discharge of individual cells is the last puzzle that every BMS must solve and which we have not yet sufficiently addressed, but it is actually one of the most important functions that the whole battery lifespan depends on. The same level of discharge and charge of each cell is important so that some cells are not overloaded and destroyed.

No two battery cells are ever exactly alike. Some always have a bit bigger or smaller capacity. Battery cells that have a slightly lower capacity discharge faster and are also destroyed faster, while the capacity of other cells remains unused. In the same way, during charging, the weakest cells are charged first and the others are only partially charged.

Balancing the charge and discharge of individual cells thus significantly increases the overall capacity, because it is not only determined by the weakest cells, and it also protects these weaker cells, so they are not damaged, shorted or leaked, which could damage the entire battery pack. In the section on BMS development, we will focus more deeply on active and passive balancing and different types of topology.

Active and Passive balancing. Source: https://www.ionenergy.co/resources/blogs/cell-balancing-battery-life/

5. Recording and communication

Compared to the previously mentioned functions, recording and communication is a relatively easy function. Because the health of the battery is a relative quantity, the BMS needs to store data on what the battery's characteristics were at the beginning so that it can compare it with other values. Thanks to this, it enables the evaluation of the battery operation, as well as its diagnostics.

Equally important is communication between the BMS and other parts of the car such as the on-board charger or charging station. The BMS also ensures that the driver's display shows how far he has traveled or when the car needs to be recharged. It is also possible to access the aforementioned history, which the BMS stores and processes.

BMS development

In order for each BMS system to be able to perform its functions correctly, several puzzles need to be overcome for its development. As we have said before, we will focus on two. The first is the Battery State Estimation. This is a value that is important both for the driver and for the system itself and its proper management.

The second is Battery Cell Charge Balancing. There are passive and active methods, as well as various active balancing topologies that need to be properly designed to optimize BMS properties.

Battery State Estimation

The state of charge of the battery is absolutely essential information for the driver. Moreover, the use of the battery could be extended if it was possible to obtain an accurate value. However, this is a complicated problem. We have already explained why this quantity cannot simply be measured and why we have to rely on qualified estimates. Today, there are three basic estimation methods - the ampere-hour method, the open circuit voltage (OCV) method and model-based methods.

The ampere-hour method is simple and easy to implement. However, in order for it to function properly, it needs the original knowledge of the state of health (which is also only an estimate) and it is negatively affected by accumulated errors and measurement errors, and over time it becomes impractical. The open circuit voltage measurement method is also considered accurate. But it can be used only if the car has rested for a long time, so it is difficult to use it in normal operation.

Various methods determining battery state of charge. Author: Jack O'Grady. Source: https://www.jackogrady.me/battery-management-system/state-of-charge

Due to all the mentioned shortcomings, model-based methods are the most common solution. Both voltage and current measurements are used. The measured current is entered into the model and the voltage is calculated using the value of the current and / or past values and parameters. The difference between the calculated and measured voltage is then inserted into an algorithm that is able to cleverly update the estimated state.

The use of intelligent logarithms, fuzzy logic, artificial neural networks and other possibilities are being investigated. Due to their excellent ability to approach nonlinear functions, these methods can achieve very accurate estimates, but the learning process required to use these options is computationally complex, making it difficult to use them in the necessary applications.

Computer models of batteries

Creating computer models of batteries, according to which it would then be possible to calculate the charge level, is complicated because it is a strongly nonlinear system. There are basically two options. The first are electrochemical models that use the electrochemical properties of the battery. And although this method is relatively accurate, in practice it is computationally complex and so several equivalent circuit models are used instead. These circuit models are widely used to estimate battery status, but their problem is that they are not as accurate.

Current research focuses mainly on the development of more accurate models, or on a combination of the current ones (electrochemical and circuit) in such a way that they are not so computationally demanding and the goal is to eventually use them in electric cars.

Battery cell charge balancing

There are no two identical battery cells in the world (or two identical batteries). Differences can be in internal resistance, level of degradation, capacity, ambient temperature, and many more. These inevitable differences between cells can cause many problems, and overall capacity can be dramatically reduced. This imbalance then causes the individual cells to be over-discharged or over-charged, which is dangerous for the battery pack as a whole, and thus charge balancing between the individual cells is of paramount importance to maintain performance and extend battery lifespan.

Passive charge balancing methods

The passive method means that the cells that have more energy than others, are discharged by resistors and the excessive energy is dissipated as heat. By discharging the excess energy from the fuller cells, the battery pack can easily be balanced.

However, this method wastes too much energy and also complicates the thermal control of the entire battery. Moreover, in this case, only overcharged batteries work, and if one battery cell is significantly weaker than others, more energy is discharged during balancing than during driving.

Active charge balancing methods

Active switching circuits are used for active balancing, which are able to transfer energy between individual cells. Unlike passive methods, only a small amount of energy is wasted. But in order to achieve this, more components need to be built into the circuit, which not only leads to a higher cost, but also to reduced reliability.

Balanced and unbalanced battery pack. Source: https://www.ionenergy.co/resources/blogs/cell-balancing-better-performance/

Active balancing occurs through a variety of strategies called topologies, which take into account cost, complexity, and reliability. As always, there's a trade-off. With the simplest and therefore the most reliable topologies, a cell can only balance another cell that is right next to it, which is insufficient if the unbalanced cells are farther apart.

To effectively connect all the cells so that their alignment can be flexible, too many components are needed and thus become unreliable and expensive. The third method, which allows for a small number of components and flexibility, is too slow to be effective in practice, as two adjacent cells are gradually aligned until a homogeneous charge is achieved.

As this is a fundamental function of BMS, much effort is devoted to designing the most efficient topologies and using the best strategies, both passive and active balancing, using as few components as possible. We can surely expect many new things to come in these segments.

In conclusion

BMS is a part of electric cars, which we do not hear about as often as, for example, the battery, but its function is completely irreplaceable. It is the BMS that protects the battery from misuse and damage, prolongs battery life and ensures that the battery is always ready for use.

However, every design always brings the need to balance the price, efficiency and longevity of each system. The only value that is never discounted is security. All components must meet ISO 26262 security standards, so each BMS must be fail-safe and contain redundant resources, such as processor units, each of which must have its own dedicated devices, such as memory, and more.

In terms of the importance and safety of the car and crew, the BMS is definitely an underestimated part of the electric car and deserves the same attention as the battery itself (if not bigger).